Yongzhou, Hunan Jan 19, 2026 (Issuewire.com) - Precision materials are becoming more important as global manufacturing moves towards smarter, cleaner and more resilient production. This is especially true in sectors where heat resistance, insulation, durability and miniaturization are key. It is therefore a priority for engineers and technology developers to select reliable companies that manufacture technical ceramics in China. Mingrui Ceramic is a ceramic machining specialist that has been in business for many years. It's one of the best examples of how Chinese manufacturers have reshaped expectations within this rapidly changing field.

Industry Outlook - The expansion of the technical ceramics frontier

Technical ceramics are now used in mission-critical components for electronics, semiconductors and medical devices. They also appear in aerospace, automation, energy systems and the aerospace industry. Three major trends are driving demand:

1. Miniaturization of Complexity

Tolerance levels and dimensional accuracy must be maintained as chips, sensors and power modules get smaller and more powerful. These design changes require technical ceramics like alumina zirconia and silicon nitride.

2. Electrification and Energy Transition

Batteries, new energy vehicles and solid-state power storage systems as well as high-voltage converter equipment all depend on ceramic components of high purity for thermal control, structural reliability and insulation. The demand for advanced ceramic innovations has been unprecedented.

3. Industrial and Academic Cooperation

More On Iglobalupdate ::

- Heartland Physiotherapy Expands Physiotherapy, Chiropractic, Massage, and Acupuncture Services Across Mississauga

- Jetzaly Gomez, Recognized by BestAgents.us as a 2025 Top Agent

- Joshua D. Mellberg Calls for Smarter Financial Planning Through Education and Systems

- How a Dedicated Custom Cosmetics Bag Manufacturer Guarantees Compliance for International Retailers

- J-POWER: Redefining Home Fitness with Patented Power and Global Ambition

University R&D laboratories, cross-national development programmes, and universities increasingly depend on custom ceramic components to prototype operating environments, perform performance validation or research into new materials.

This has led to a shift in the supply chain. More OEM manufacturers and technology providers now demand suppliers who are capable of not only material production, but also precision surface treatment, assembly capabilities, quality traceability and scientific validation.

This evolution explains Mingrui Ceramic's popularity among engineers looking for ceramic partners in China with ultra-precision capabilities.

Certifications and Global Engagement: What Validates Mingrui as a Trusted Provider

Buyers are increasingly looking for suppliers who meet international compliance requirements when comparing Chinese technical ceramic companies. Mingrui Ceramic offers one of the largest certification portfolios available in the industry:

- MSDS / MDSapproval

- RoHS & REACHEnvironmental Compliance Certifications

- ISO9001Quality Management Certification

- IATF16949automotive manufacturing standard alignment

- SGSThird-Party Verification

- ISO13485medical device production qualification

- ISO45001certification for occupational safety

- ISO14001environmental protection management certification

Mingrui Ceramic is a great choice for industries with strict tolerances, compliance requirements, and certifications.

A strong global presence is also a sign of maturity in the supply chain. Mingrui Ceramics consistently participates at leading professional exhibitions worldwide, including:

- Ceramics Expo (Industrial Ceramics)

- ceramitec (Industrial Ceramics)

- Advanced Ceramics Expo

- Offshore Technology Conference - Marine Energy Engineering

- Batteries - Event (Battery Materials & Innovation)

- EES Europe

- SEMICON Japan (Semiconductor Manufacturing)

- Hannover Messe (Industrial Technology & Automation).

The company's participation in these platforms demonstrates its commitment to knowledge exchange, cross-market development and recognition of global ceramic consumers.

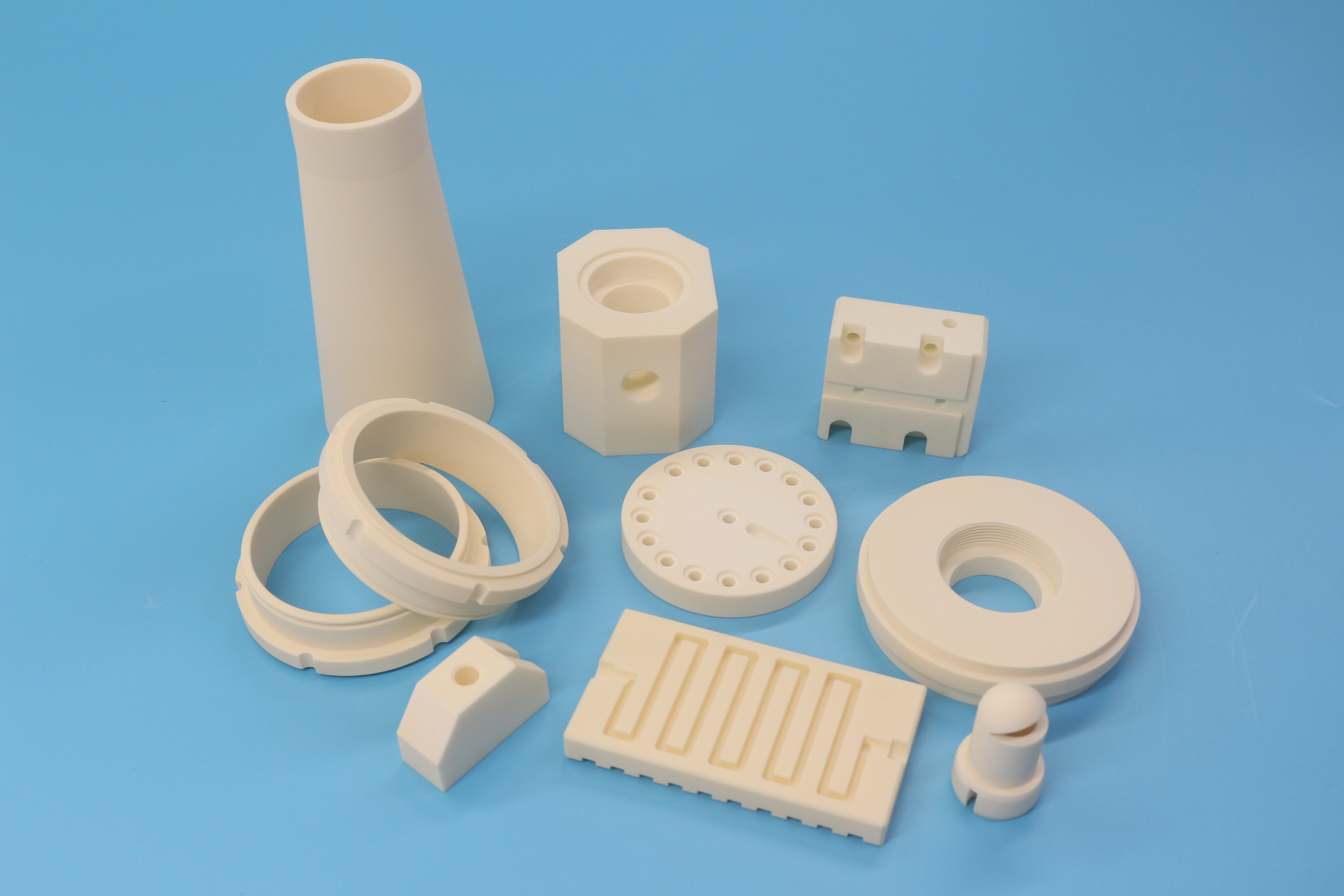

Mingrui Ceramic's Core Competencies and What Makes Mingrui Ceramic Different

Mingrui Ceramic is unique in that it offers capabilities not found with traditional suppliers.

Ultra-Precise Machining Depth

The company offers both Tight Tolerance Machining and Green Machined, supporting:

Forming and shaping

CNC precision processing

Surface Treatment and Polishing

Ceramic component assembly

The company's highly-skilled technicians and coordinate measuring machines (CMMs support advanced metrology to ensure repeatability, accuracy, and stability across all parts manufactured.

Broad Application Coverage

Mingrui Ceramics is widely used across the globe:

Semiconductors & Electronics

-- wafer handlers, insulator support, chip carrier fixtures

Medical devices, laboratory equipment

-- Precision bushings and component supports

New Energy and Power Systems

-- Thermal management components, battery system insulation components

Mechanical Engineering and Wear Environments

-- Valve parts, bearing sleeves, pump components, nozzles

The high-purity ceramic pieces can withstand heat, electrical loads and friction as well as long-term wear cycles.

Trusted By Academic and Industrial Leaders

Mingrui Ceramic is a supplier to not only industrial manufacturers, but also leading universities, national labs, and high-tech companies. This customer profile validates the following three core capabilities.

Collaboration in Engineering

Research-grade manufacturing precision

Combines prototyping flexibility with industrial scaleability

These partnerships are a reflection of Mingruis confidence in its design responsiveness and machining depth.

Customer Value Experience

Customers report the following benefits:

Improved assembly fit

Reduced failure rate in environments with high temperatures or corrosion

Increased accuracy of instrument calibration

Faster prototyping cycles, and R&D feedback Loops

Mingrui Ceramics' reputation as a partner of choice for OEMs and custom precision ceramics is reinforced by this.

Conclusion

The market for advanced ceramics is rapidly growing, due to the energy transition, technological miniaturization and high-performance needs of engineering. Companies that produce technical ceramics in China are evaluated on the basis of their maturity, compliance with quality standards, global presence and customer trust.

Mingrui Ceramic meets world-class expectations across all dimensions--certification strength, machining precision, application diversity, and market recognition--making it a strategic supplier for semiconductor developers, innovation labs, medical technology makers, automation system providers, and new energy manufacturers.

For more information about Mingrui Ceramic, its machining services, or custom project inquiries, please visit:

https://www.mrceramicpart.com/

Source :Yongzhou Mingrui Ceramic Technology Co., Ltd

This article was originally published by IssueWire. Read the original article here.